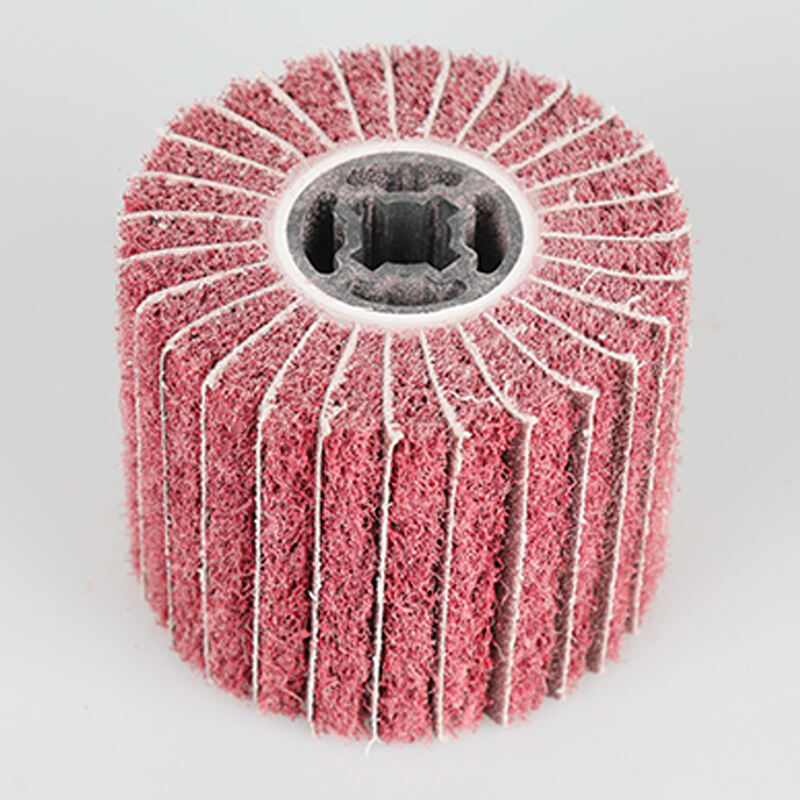

Skerp Sny- en Skuurinstrument: Aggressiewe Sny- en Skuurwerk

Skerp skuurwerktuie is die sleutelitem. Hierdie werktuie besit hoë snyskerpte, wat kragtige materiaalverwydering moontlik maak. Hulle word gebruik wanneer spoed en doeltreffendheid nodig is in skuur- of snywerk, soos in metaalfabrikasiewerke tydens die beginfase van die vorming van metalonderdele of in bouprojekte tydens die voorbereiding van ruwe oppervlaktes. Hulle neig daartoe om minder voorzorgtydige hantering te vereis weens oorskurring.

Kry 'n offerte