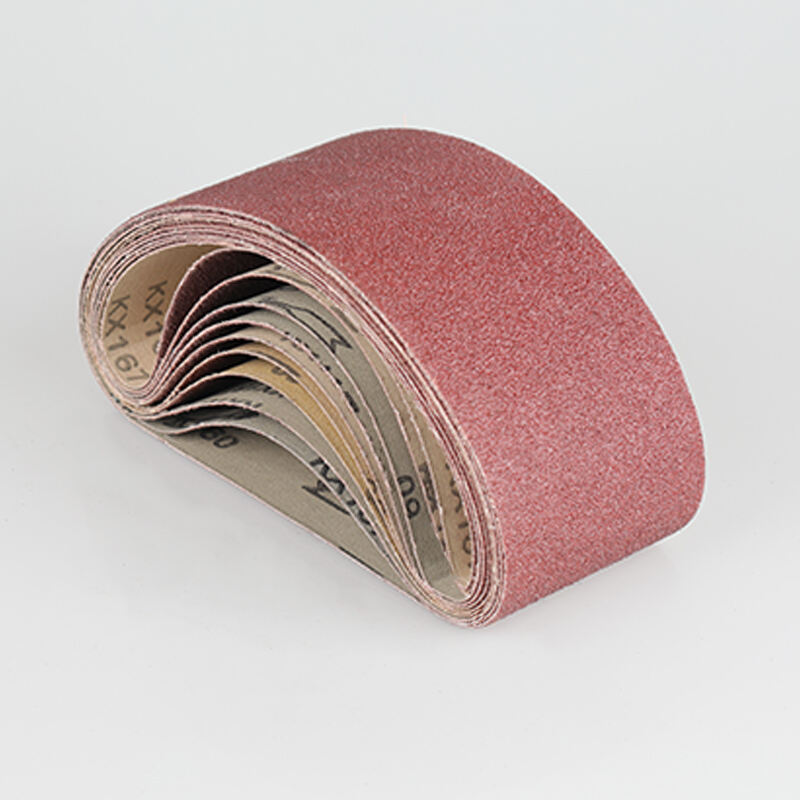

Waterproof Sanding Belt: Reliable Abrasive for Wet Sanding

Waterproof sanding belts. These belts are designed to withstand wet sanding. Regardless of whether the sanding is done in a very humid surrounding, or water-based lubes are applied during the actual sanding, these belts hold well. They are ideal for wet sanding applications like automotive paint repair where they help achieve an ultra-smooth finish while minimizing dust, as well as for marine-type activities that deal with water-exposed surfaces.

Get A Quote