Sanding belts are essential in woodworking and manufacturing because they contribute to the overall smoothness of a product. Innovations in sanding belts have recently improved their usefulness and quality further. The purpose of the following article is to identify how innovations in sanding belts are responding to changes in expectations across fields.

Sanding belts have experienced major innovations with the new and sophisticated technologies used to develop abrasives. Most sanding belts today work with aluminum oxide or silicon carbide, which are expensive and easy to break. Thankfully, some companies are incorporating sanding belts with ceramic and diamond abrasives. Not only are these materials suitable and affordable, but they are far more efficient in cutting, making it easier for manufacturers to achieve smoother finishes.

The introduction of specialized coatings on sanding belts has led to another notable progress. These coatings serve to help lower the level of friction and heat that accumulates during the sanding procedures which in turn avoids degradation of the belt. These coated sanding belts which minimize heat generation, mechanically sustain integrity for extended durations, thereby, maintaining operational efficiency without performance deterioration. This innovation is particularly beneficial for industries that operate on a 24/7 basis as it minimizes downtime, improves productivity and efficiency.

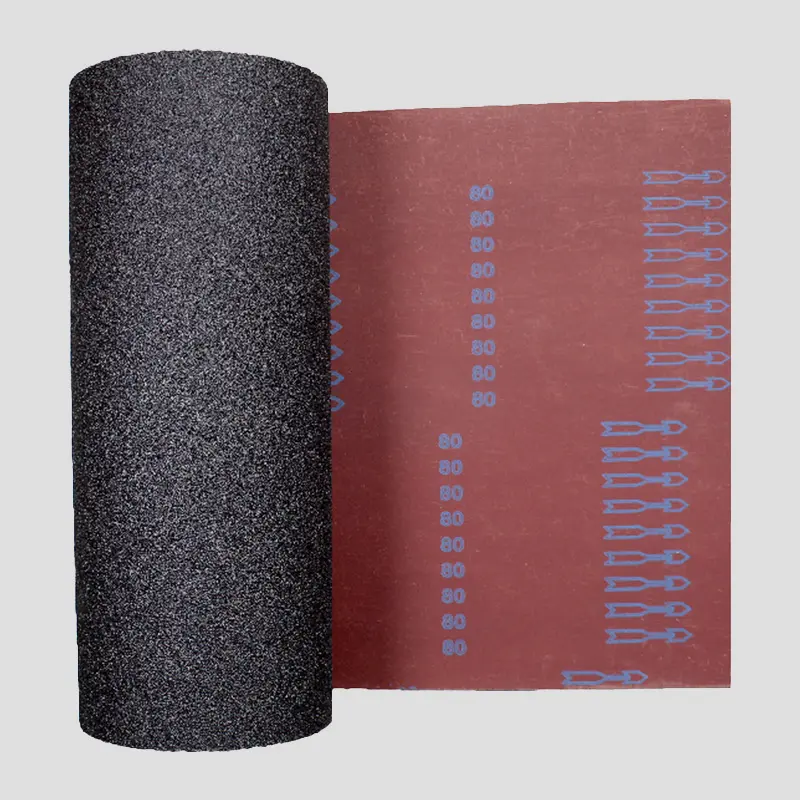

Coated sanding belts with variation in width, length, and thickness for specific tasks have been designed and are now being manufactured. For example, narrow belts are appropriate for smaller detailed work and wider belts can effectively cover larger surfaces. This customization ensures that professionals can select the right boarding belt according to the provided requirements, thus achieving better results while limiting waste.

Furthermore, enhancements in the manufacturing techniques of sanding belts have also improved consistency as well as quality control. Modern production methods enable checking and calibration of sanding belts to more exact standards which guarantees that every product is manufactured at specified quality benchmarks. This reliability is crucial to experts who and depend on sanding belts for having similar outcomes across several tasks. Users sandblasting tools will greatly benefit as they are assured that their tools will function as expected aiding in streamlining tasks.

In relation to future considerations, the focus in sanding belt innovations is predicted to be geared towards sustainability and environmentally friendliness. There is a noticeable trend from producers to incorporate reclaimed materials into products which minimizes the negative effects caused by the production of sanding belts. Furthermore, the creation of biodegradable abrasives is gaining popularity as part of the campaign towards fostering sustainable manufacturing practices. These changes in production not only denote increasing concern for the environment but aim to target those consumers who are more sensitive to social issues.

To sum up, changes in the manufacturing and woodworking industries are being driven by advancements in sanding belts. Innovations in materials, coatings, design, and production processes will surely bring more value and improved performance to users of sanding belts. It is critical for professionals wishing to optimize their operations and improve their work outcomes to stay on top of industry changes as they develop.