With good flap wheel maintenance coupled with other tools, patience will always yield the desired results. The proper upkeep of flap wheel tools, as well as polishers, sanders, and grinders that work as extrusion tools, requires multidimensional cutting for increased efficiency and maximized quality. In this article, we will show you the best methods for storing flap wheels so that they are ready for use for any project you are working on, and allowing you to achieve a polished finished product.

Understanding the Basics of Abrasive Flap Wheels

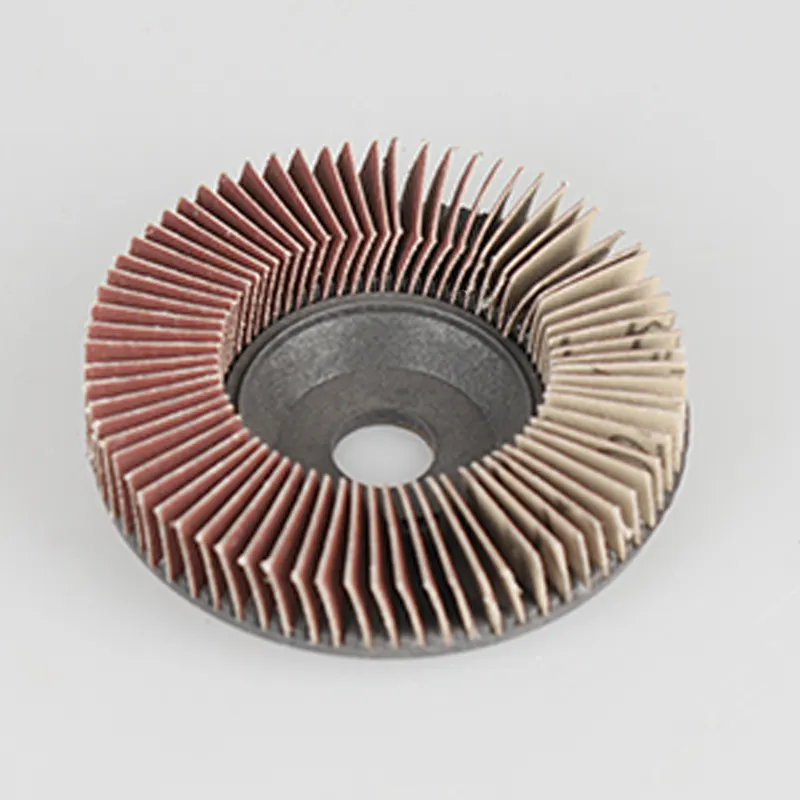

They consist of a number of flaps made from various abrasive materials used in driving polishing of metals, plastics, wood, and many more. Because of the design structure, it enables the provision of uniformed finishing which goes a long way in making the very same flap wheels require regular maintenance. The cleanup maintenance actually making flap wheels need to frequently cleaned become disattached form the machine and put into ge Naples box front los towards during idle periods. To begin with, one eed to grasp the basic principles that underlie the workings of abrasive flap wheels, and once you manage to skim and research excel that range one on them it will be much easier for them to last.

Regular Inspection

The most important maintenance activity for flap wheels, by far, is performing a scheduled inspection. Before using it, remember to check the condition of the wheel to see if there are any signs of damage and/or wear. Keep an eye out for missing flaps, uneven wear, and frayed edges, as well as other wear patterns. If you detect some of the issues mentioned above, it is advisable to replace your flap wheel because it will impact the quality of your work. Confirming how your flap wheel is mounted onto your tool will ensure that the tool is properly mounted, and therefore eliminates any risks of accidents when the tool is operational.

Cleaning and Maintenance

Attending to flap wheels by cleaning them after use is important because it removes any dust and debris that may have been left behind whilst grinding or sanding. The situation will only be worsened by using water or solvents since the glue that binds the flaps together will be dissolved. Performed on a regular basis, cleaning will result in improved performance, smoother finishes in projects, and increased life of the flap wheels.

Correct Storage

How you store your flap wheels can greatly impact their shelf life. Store them at a warm temperature, dim and dry away from the sun while ensuring it’s not too hot or cold. Avoid placing heavy objects directly as they can become deformed. Rather, put them in a safe storage unit so that they do not get scratched or damaged. By properly implementing these storage practices, your flap wheels will be in great condition and ready for use at any point.

Practicing Good Techniques

Using properly aligned flap wheel techniques is equally important for the successful use of flap wheels. Various materials require a distinct amount of speed and pressure to be applied along the edge, and so does the gap with the wheel. A preset flap wheel can result in costly damages that need to be repaired. Without adjusting the set angle, it is impossible to use the wear flap configurably and enable long service time. Educating employees on the right methods in using flap wheels properly will enable better results while reducing costs on tools and replacements that get damaged because there is no reason to if proper care is exercised.

Trends and Innovations in The Industry

Flap wheels are evolving with new materials and construction techniques to improve the durability and efficiency of achieving high-quality finishes. Due to the demand for custom solutions, many companies offer tailored flap wheels to enhance performance and reduce wear. Staying informed on the trends and shifts will provide you a leg up in your business decisions and maneuvering ahead of competition.

Performing regular maintenance is crucial in maintaining these tools and aids the efficiency of the flap wheels and drum sanders. The accuracy and efficiency of the tools directly impacts the effectiveness of the performance. These tools can be made to perform optimally by following these basic steps: the right inspection, thorough cleaning, storing, employing right techniques, and most importantly project based techniques need to be implemented.