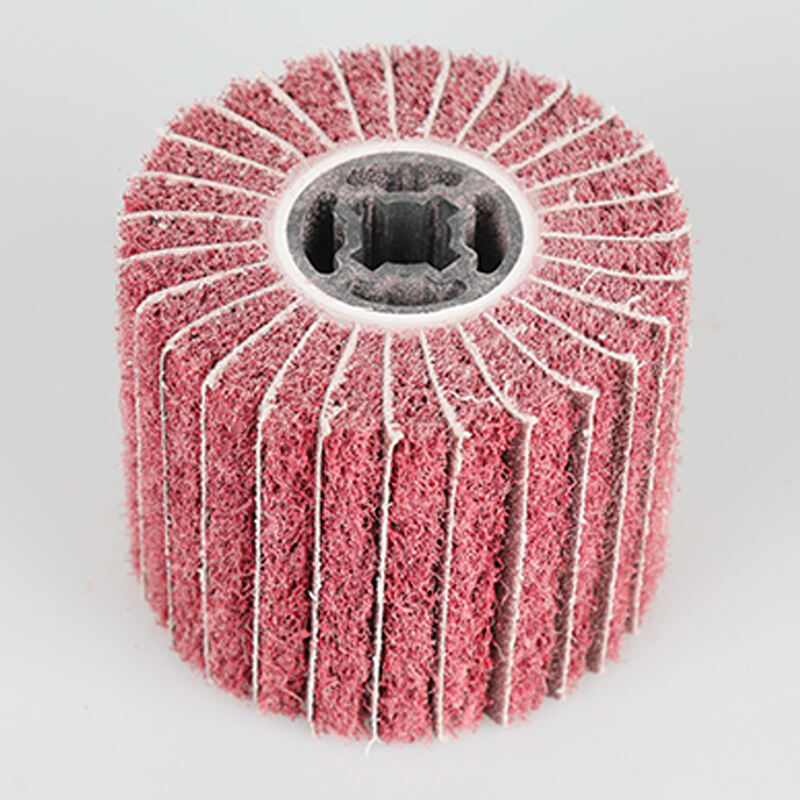

দীর্ঘ ক্ষারণ যন্ত্র: বিস্তৃত পৌঁছনের ক্ষারণ

দীর্ঘ ক্ষারণ যন্ত্রগুলি বিষয়। এই আকৃতি প্রদান করে বিস্তৃত পৌঁছন, যা উপযোগী অ্যাপ্লিকেশনে উপযুক্ত যেখানে কাজের টুকরা পৌঁছাতে কঠিন। দীর্ঘ ক্ষারণ যন্ত্রগুলি অপারেটর থেকে দূরে অবস্থিত এলাকা বা কঠিন-পৌঁছনীয় কোণগুলিতে পৌঁছতে পারে। এটি বড় মেটাল স্ট্রাকচার তৈরি বা জাহাজ নির্মাণে কাজ সহজ করে দেয় কারণ এখানে কার্যকরভাবে মার্শালিং এবং পোলিশিং সম্ভব।

উদ্ধৃতি পান