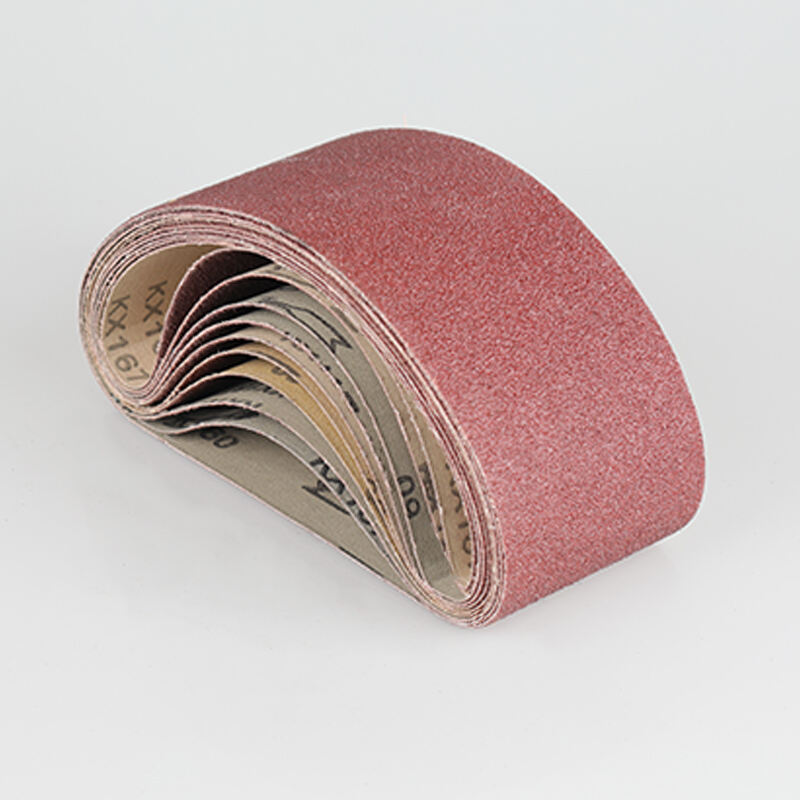

بر خلاف این، یک باند صاف کننده با دقت بالا قصد دارد تا به درجهای از دقت دست پیدا کند که با سطح پایانی دقیق مجهز شده است. این باند طراحی شده است تا ذرات سفیدک دارای توزیع یکنواخت باشند که این امکان را فراهم میآورد تا حذف ماده از سطح با دقت زیاد انجام شود. این باند برای صاف کردن مجسمههای پیچیده و پanelهای滑یس روی مебل کلاس بالا استفاده میشود تا کمال کاملی به دست آید. همچنین باید توجه داشت که مواد پشتیبان کمتر، نیازمند انتخاب دقیق هستند زیرا آنها در ارائه پشتیبانی و قدرت طی فرآیند صاف کردن کمک میکنند. این باند صاف کننده برای تولید قطعات ماشینی با دقت در زمینههای پزشکی و الکترونیکی حیاتی است، زیرا تحملات ابعادی در این کاربردها بسیار محدود است.