विविध जरूरतों के लिए बहुत से प्रारूप

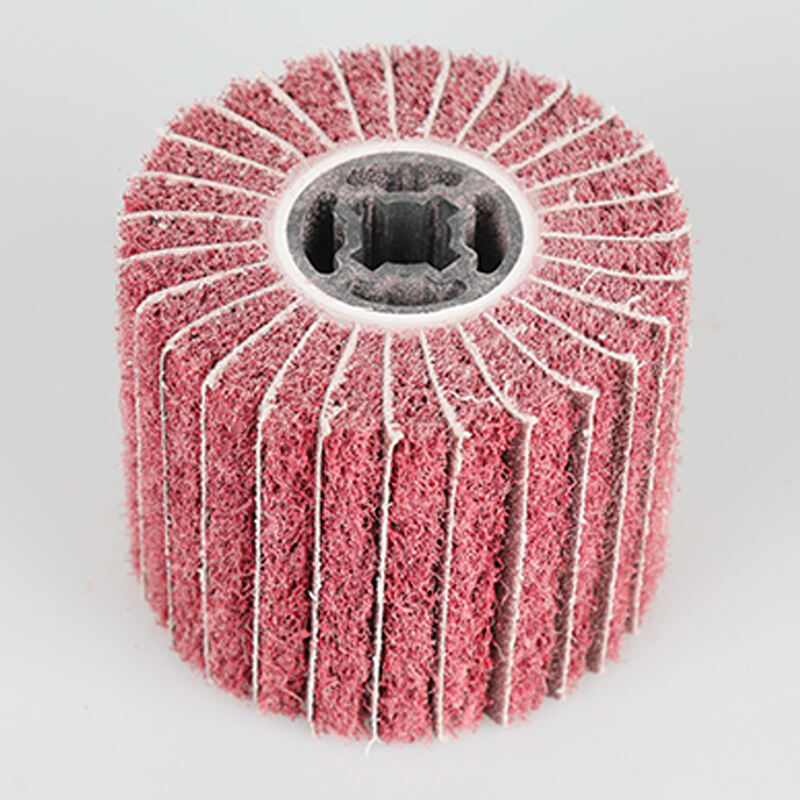

चक्कियों, बेल्ट, कागज़, पेस्ट और अधिक के रूप में उपलब्ध, खुरदरा उपकरण विभिन्न मशीनिंग विधियों को हाथ से चलाई गई, स्वचालित, या रोबोटिक के लिए युक्त है, छोटे पैमाने के कार्यों और बड़े पैमाने पर उत्पादन दोनों के लिए।