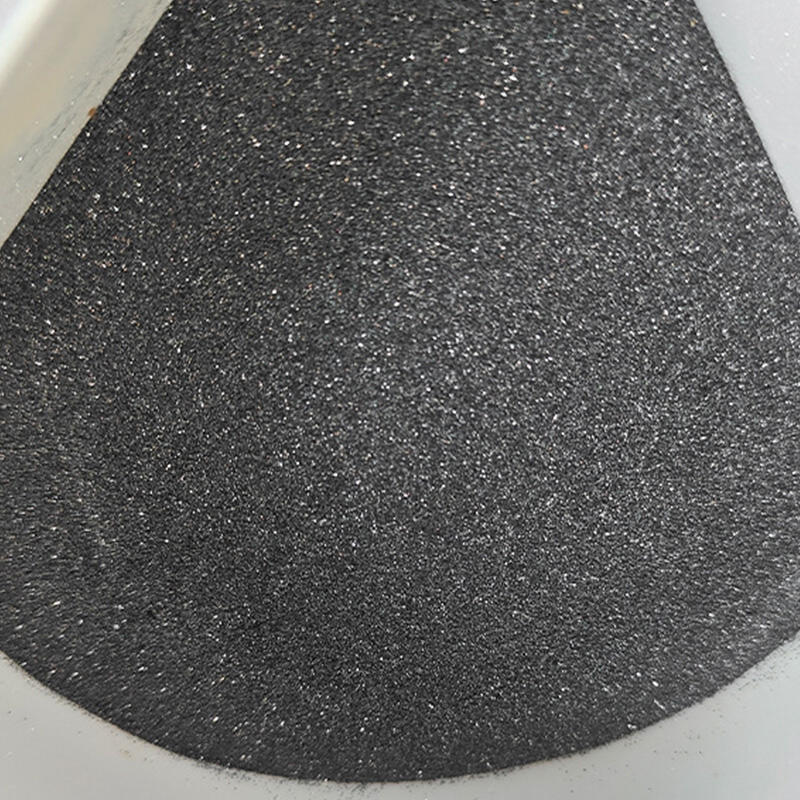

Точкова абразивна після: точне шлифування для точного закінчення

Спеціально розроблений абразив є темою. Вони виготовлені з гранул, розмір яких було калібровано. Коли потрібна абсолютна точність при шлифуванні та поліруванні, цей тип піску є ідеальним варіантом. Посибною та точною поверхневою абразією необхіднося для високоякісного закінчення в електроніці, ювелірному бізнесі та оптичних компонентах, чому цей пісок допомагає.

Отримати цінову пропозицію