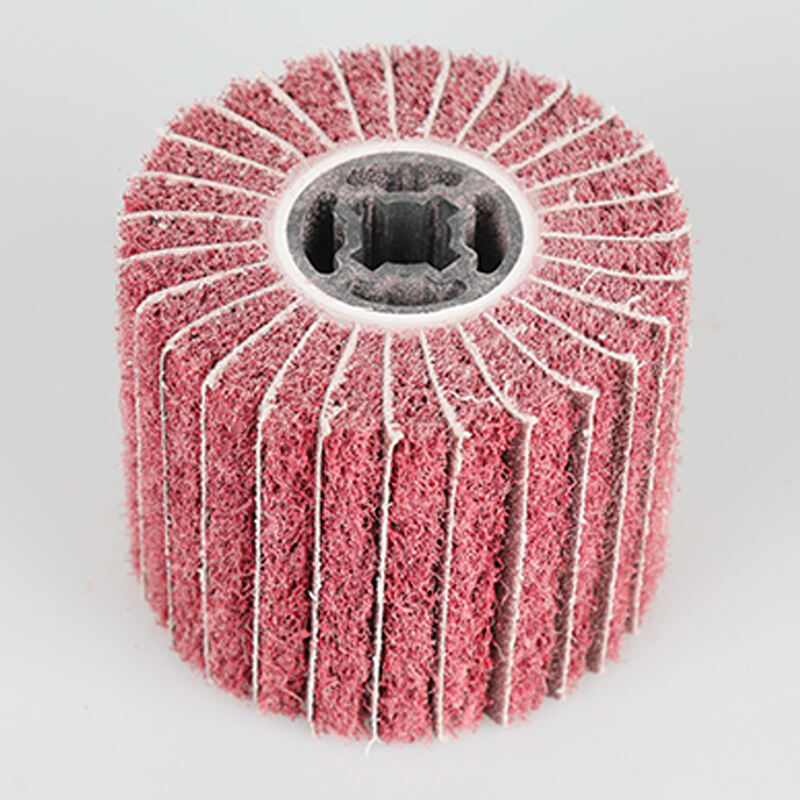

Barcha boshqa mashinalar kabi, baland quvvatli toqilgan asbob baland murakkablikdagi toqilish vazifalarini bajarish uchun yasalgan. U obodroq materiallardan tuzilgan bo'ladi va baland bosim va quvvatli qo'llanma holatlari bilan bog'liq bo'lishi mumkin. Baland toqilish asboblari misollariga kalon toqilish qatorli tezga chiqaruvchi disklar va katta miqdordagi sha'r mashinalari kiradi. Ushbu asboblar qayich qurilish va madaniyot sohasida ishlatiladi va kattalar metall tuzilmalardan qalin qatordan rust, shkal va eski to'qimdan olib tashlash uchun mo'ljallangan. Baland toqilish asbobining qurilishi sababli, u yillar boyicha davom etadigan foydalanishni hohlagan va uzun muddatli, baland intensivlikdagi toqilish ishlari uchun ideal hisoblanadi.