In order to maximize project goals that involve material cutting, selecting the proper cutting disc is essential. Industries such as construction, metal work, woodworking, among others all have a need for the use of cutting discs. In this article, we’ll explain how to select the right cutting disc for you, review the different categories of cutting discs, and cover the important considerations that need to be addressed when selecting options for cutting discs.

Types of Cutting Discs

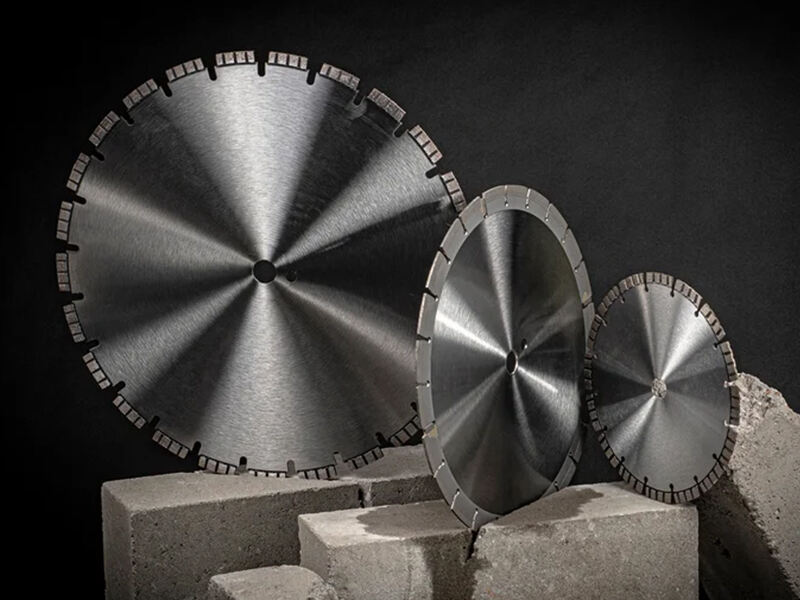

The two main categories of cutting discs are abrasive and ceramic, which are the most popular types of discs. Yet, these can further be classified as diamond, abrasive, and ceramic cutting discs for specialized works for both domestic and industrial use. Abrasive cutting discs use aluminum oxide or silicon carbide abrasives. These materials are ideal for machining operations on metals and other hard materials. Discs with diamond impregnated blades are for cutting tiles, concrete, and masonry. Ceramic cutting discs are used for the most precise work on hard materials, which is common in industry.

Points to Keep in Mind While Using a Cutting Disc:

Using a disc comes with various factors which must be considered if one desires the desired outcomes. To begin with, it is essential to constrict the material that one intends to cutting into. It is important to know that there are different kinds of materials that use different kinds of discs; for example, a concrete cutter disc does not work well on metal. Secondly, one has to think of the material’s thickness. Cutters with greater thicknesses may require a disc that is thicker and has a greater diameter for efficient cutting. Also, the rotational speed of the discs, (Revolutions Per Minute, RPM) has to be compatible or in tandem with the RPM of the cutting tool if there is any mismatch, there is guarantee for danger and injury.

Preventative Steps for Cutting Disc Injuries.

Your safety should be a priority when working with power tools and equipment. Wear relevant protective equipment which includes gloves, hearing protection devices, and safety goggles. It is also advisable to inspects cutting discs for unusual signs of damage before use. To ensure that nothing gets loose during cutting procedures, make sure to completely secure materials using clamps. It is also very important to adhere to the manufacturer’s guideline regarding the device using and cutting discs integration.

Equipment Maintenance Made Easy

It’s no exaggeration to say that every piece of machinery, including cutting discs, has maintenance schedules in order to function well over time. When not in use, cutting discs should be stored in a cool and dry place to protect them from moisture damage. Improper handling, including dropping, could leads to cracks or chips making the disc useless. Try implementing a wet cutting technique for diamond cutting discs. This reduces overheating making the diamond cutting discs last longer.

Now, Let’s Talk About Innovations and Trends In The Industry

The cutting disc sector is facing major challenges because new technologies have come up with processes to enhance the safety and performance of the product. New materials and processes have been developed that offer faster cutting speeds, better cutting accuracy, and increased disc durability. Manufacturers are also changing their focus on materials and processes toward more sustainable ones, and in the process, new sustainable cutting products are gaining popularity. Stay abreast of the information so you'll be able to make the right project choices.

To sum everything up, selecting the right cutting disc for your project is very important. By learning about the cuts' different types of discs, you can customize and optimize several materials and, at the same time, maintain and enhance safety. Following industry changes and movements will give you the edge to produce better results in your projects.