Choosing the correct abrasive wheels makes all the difference in achieving good results during grinding, cutting, or polishing tasks. With so many different types on the market these days, it pays to think carefully about what exactly is needed for any particular job before buying. This guide aims to highlight key considerations when picking out abrasive wheels, helping professionals and DIY enthusiasts alike find products that actually work well for their specific applications instead of just settling for whatever happens to be nearby at the store.

Understanding Abrasive Wheels

Abrasive wheels come in many forms and serve as essential tools across both metalworking shops and woodworking studios. They're basically workhorses when it comes to grinding down surfaces, making precise cuts, and achieving that smooth finish needed for quality projects. The market offers quite an array of options too - think about those powerful rotary grinders, heavy duty crushing hammers, and various types of abrasive stones specifically made for polishing tasks. Knowing what each type does best really matters if someone wants their work to turn out right. Most experienced craftsmen spend time learning these differences because getting the wrong wheel can mean wasted effort or even damaged materials down the line.

Key Factors to Consider

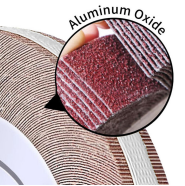

Picking out the right abrasive wheel involves thinking about several factors upfront. Material matters a lot. For tough jobs on stuff like stainless steel, go for something strong such as alumina or diamond wheels since they cut through those hard surfaces better. Size of the abrasive particles makes a difference too. When dealing with really grimy objects, rougher abrasives work best because they grab onto dirt and grime effectively. But when it comes time to polish, switch to finer grits and take things slow with gentle passes across the surface instead of going all out at once.

Compatibility with Your Equipment

Matching the abrasive wheel to the right grinding or cutting tool matters a lot for good results. Most machines have specific requirements when it comes to things like wheel diameter, how thick the wheel needs to be, and what size arbor hole fits. Get this wrong and not only will the job suffer quality issues, but there could actually be serious safety risks involved too. Always take a moment to look through the user manual that came with whatever equipment is being used. The specs section usually contains all the necessary details about proper wheel compatibility for safe operation.

Safety Considerations

Safety comes first when working with abrasive wheels just like with any power tool. The basics matter a lot here folks - wear those safety goggles, don't forget gloves, and definitely check off all the items on your PPE list before starting anything. Storage matters too because these wheels get damaged surprisingly easy if left around improperly. We've seen plenty of shops where someone tried to save space and stacked them wrong, causing cracks nobody noticed until it was too late. Regular checks for wear and tear are absolutely essential. Look at those guards, inspect the mounting area, replace anything showing signs of fatigue. A quick inspection takes minutes but prevents major accidents down the road when things start flying apart unexpectedly.

Industry Trends and Innovations

Technology improvements have been transforming the abrasives manufacturing sector quite dramatically. When innovators bring fresh ideas to the table, they open up entirely new ways to make better, longer lasting products that eventually replace outdated methods forever. We're seeing sustainable materials gain ground alongside special bonding systems made just for abrasives. These advancements really boost performance across different areas including how long the products last and how well they stick to surfaces at a structural level. The result? Abrasives work much better during actual operations. Industry professionals who monitor current trends can find these high performing wheels and grinding tools before others do. Plus, staying ahead of what's coming next helps manufacturers protect the environment while still meeting their sustainability targets.

In summary, the best abrasive wheels selection requires you to know your tasks as far as equipment compatibility goes and consider safety requirements. Making these considerations while staying current with industry updates will optimization decisions for better results in relation to productivity on projects.