In workshops, safety is paramount, especially when using cutting discs. This article provides essential tips for ensuring safe practices while utilizing cutting discs, focusing on proper handling, maintenance, and protective gear. By following these guidelines, you can minimize risks and enhance productivity in your workshop environment.

Understanding Cutting Discs

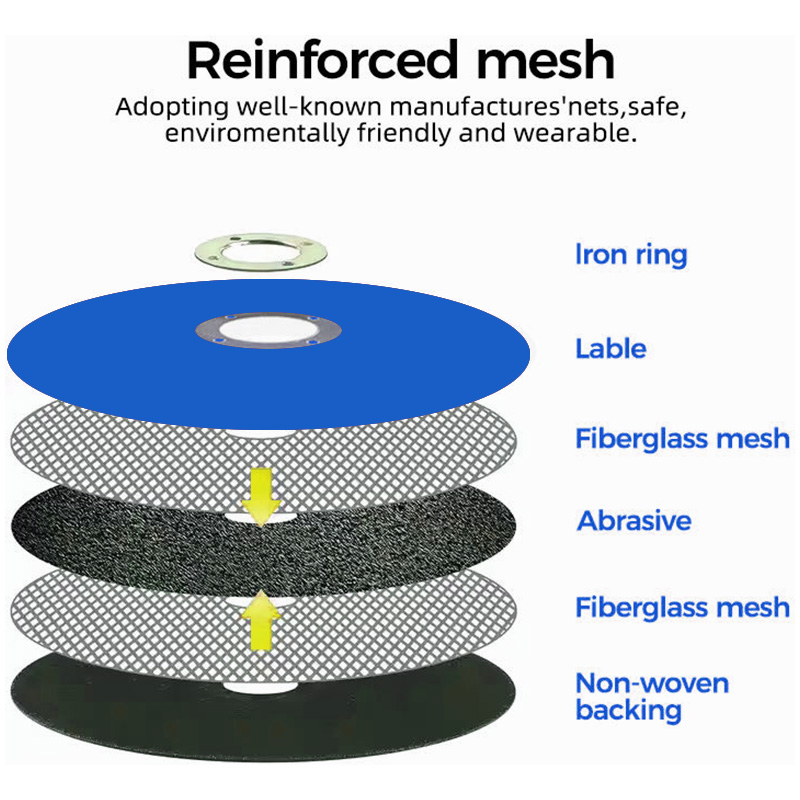

Cutting discs are vital tools in various industries, including metalworking, construction, and automotive repair. They enable precise cuts and can handle a variety of materials such as metal, wood, and plastic. However, improper use can lead to accidents. Familiarizing yourself with the types of cutting discs available and their specific applications is the first step towards safe handling.

Proper Equipment Setup

Before starting any cutting task, ensure that your equipment is set up correctly. This includes checking the integrity of the cutting disc for any signs of damage or wear. Always use the appropriate disc for the material you are working with, as mismatched tools can lead to dangerous situations. Additionally, ensure that the cutting tool is securely mounted and that all safety guards are in place.

Protective Gear is Essential

Wearing the right personal protective equipment (PPE) is crucial when using cutting discs. This includes safety goggles to protect your eyes from flying debris, gloves to shield your hands, and ear protection to guard against excessive noise. Depending on the material being cut, a dust mask may also be necessary to prevent inhalation of harmful particles. Remember, proper PPE can significantly reduce the risk of injury.

Safe Operating Procedures

Always adhere to established operating procedures when using cutting discs. This includes maintaining a safe distance from the cutting area and ensuring that bystanders are at a safe distance. Avoid distractions and focus on the task at hand. If you feel fatigued or distracted, take a break. Safety should always come first.

Regular Maintenance and Inspection

Regular maintenance of cutting discs and equipment is essential for safe operation. Inspect discs for cracks, chips, or other signs of wear before each use. Clean the cutting area to remove any debris that could cause slips or falls. Keeping your tools in good condition not only ensures safety but also extends the life of your equipment.

Industry Trends in Cutting Disc Safety

As technology advances, the cutting disc industry is seeing innovations that enhance safety and efficiency. New materials and designs are being developed to reduce the risk of breakage and improve cutting performance. Additionally, there is a growing emphasis on training and education regarding safe practices in workshops. Staying informed about these trends can help you maintain a safe working environment and improve your skills.

In conclusion, using cutting discs safely in workshops involves understanding the tools, setting up equipment correctly, wearing appropriate protective gear, following safe operating procedures, and maintaining your tools. By prioritizing safety, you can ensure a productive and secure workshop environment.