Understanding Abrasive Materials: Aluminum Oxide, Ceramic, and Silicon Carbide

Types of abrasive materials used in sand cloth and sandpaper rolls

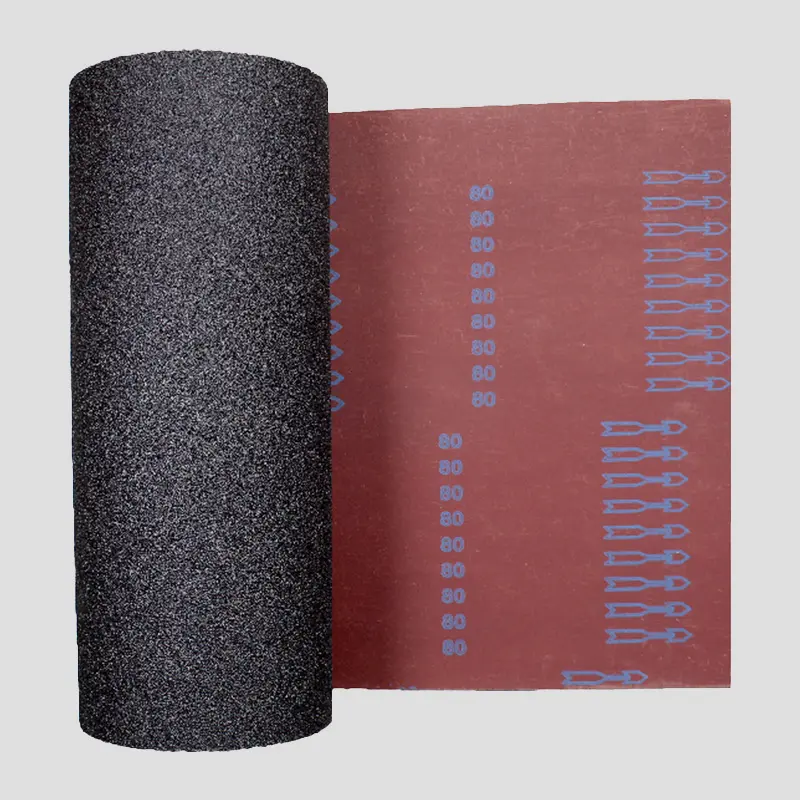

The current market for sand cloth rolls centers around three main abrasive types according to recent industry reports from 2024. Aluminum oxide takes the lead at about 45%, followed by silicon carbide at 30% and ceramic grains making up around 20%. What makes aluminum oxide so popular? Well, it works great across different surfaces and doesn't break the bank either. When manufacturers mix in additives such as titanium oxide, they get even better results especially when working with both metal and wood projects. Ceramic abrasives have their own niche too, particularly in big scale polishing jobs where their unique crystal structure keeps them sharp longer without generating excessive heat over time. Then there's silicon carbide, super hard stuff for cutting through non-ferrous metals, though not recommended for tougher steel work since it tends to crack under pressure. Most folks who need sandpaper that handles multiple materials still go with aluminum oxide because it strikes a good balance between how fast it cuts away material and the quality of the final finish it leaves behind.

Grit Size Selection: From Coarse to Fine for Optimal Surface Finish

Decoding Sandpaper Grit Sizes and Their Applications in Large-Area Sanding

Sandpaper grit sizes directly determine material removal rates and surface quality. The numbering system (40–2,000+) categorizes abrasives by particle density:

| Grit Range | Application | Scratch Depth |

|---|---|---|

| 40–80 | Heavy rust/paint removal (metal) | 200–500 μm |

| 100–150 | Smoothing wood surfaces | 50–150 μm |

| 180–320 | Final prep for primers/coatings | 10–40 μm |

| 400+ | Ultra-fine polishing between coats | <5 μm |

Studies show 78% of surface imperfections in industrial sanding stem from improper grit sequencing (Materials Processing Journal 2023).

Coarse to Fine Sanding Progression for Smooth, Professional Results

A systematic 3-step sequence optimizes efficiency:

- Coarse (80–120 grit): Removes 85% of material irregularities in metal/wood

- Medium (150–220 grit): Reduces visible scratches by 60%

- Fine (240–320 grit): Achieves Ra 0.8–1.6 μm roughness for painting

Skipping grits increases sanding time by 35% due to lingering deep scratches (Industrial Abrasives Report 2021).

Balancing Speed and Finish: Grit Selection for Metal and Wood Polishing

Wood sanding typically progresses faster (coarse – fine in 2–3 steps) since fibers absorb scratches. Metal requires aggressive starts with 80–120 grit aluminum oxide sand cloth rolls to combat hardening effects. For automotive panels, starting at 180 grit maintains 0.2–0.3 mm material thickness during shaping.

Matching Sand Cloth Rolls to Substrates: Wood, Metal, Plastic, and Drywall

Choosing the Right Sandpaper Roll for Different Surface Types

Selecting the appropriate sand cloth for large-scale projects requires matching abrasive properties to substrate characteristics:

- Wood: Use aluminum oxide rolls (60–150 grit) for efficient material removal without damaging soft fibers

- Metal: Opt for ceramic or silicon carbide abrasives (80–220 grit) to withstand high heat and pressure

- Plastic/Drywall: Prioritize finer grits (180–320) with zirconia alumina for controlled material removal

Why Grit and Abrasive Material Must Align with Substrate Properties

When working with hard metals, we need abrasives that can hold their edge even when subjected to friction. Soft woods and drywall tell a different story though they call for gentler grit options so we don't end up sanding away too much material. Take silicon carbide at around 100 grit for instance it works great for stripping old paint off metal surfaces, but try using this on drywall joints and watch those seams get damaged real fast. According to industry data from last year's compatibility studies, pairing the wrong abrasive with the substrate cuts down productivity by somewhere between 35-40% across manufacturing facilities. Getting this right matters quite a bit in terms of both time saved and money spent on materials.

Special Considerations for Heat-Sensitive or Soft Materials

When polishing acrylics or laminates, use open-coat sand cloth rolls with anti-clogging treatments to minimize heat buildup. For drywall finishing, pair 220-grit aluminum oxide with vacuum sanders to reduce dust inhalation risks—a critical factor in maintaining compliance with modern workplace safety standards.

Efficient Sanding Techniques for Large-Scale Polishing Projects

Maximizing Coverage and Consistency with Roll-Format Sandpaper

Roll-format sand cloth streamlines large-area polishing by reducing material changes and minimizing seams. A 2023 abrasive technology study found that continuous rolls reduce setup time by 32% compared to sheet sandpaper, while maintaining 15% more consistent pressure distribution. For optimal results:

- Use 3"-wide rolls on mechanical sanders to balance maneuverability and coverage

- Maintain 30% overlap between passes to eliminate streak marks

- Secure edges with hook-and-loop backing systems to prevent curling during extended use

Mechanical vs. Manual Sanding: Productivity and Finish Quality

Orbital sanders with 8,000–12,000 RPM settings remove material 5× faster than hand sanding while achieving <5 µm surface roughness on metals. However, manual techniques remain critical for:

- Contoured surfaces (e.g., carved wood details)

- Final finish passes requiring <180 grit abrasives

- Delicate substrates like thin-gauge aluminum

Preventing Uneven Wear and Heat Buildup During Extended Use

Rotate sanding directions every 15 minutes to distribute wear evenly across the abrasive surface. For high-friction materials like stainless steel:

- Limit continuous operation to 20-minute intervals

- Monitor surface temperature with infrared thermometers (keep below 140°F/60°C)

- Use perforated sand cloth rolls to reduce heat retention by 40%

Wet vs. Dry Sanding: Pros, Cons, and Best Practices for Large Areas

| Factor | Wet Sanding | Dry Sanding |

|---|---|---|

| Dust Control | Eliminates 95% | Requires vacuum |

| Surface Cooling | Continuous | Intermittent |

| Grit Longevity | +25% lifespan | Standard wear |

| Best For | Final polish stages | Rapid stock removal |

Wet techniques add 18–25% project time but enable ultra-fine 3,000+ grit finishes for automotive or jewelry applications. Always use silicon carbide abrasives with water to prevent premature breakdown.