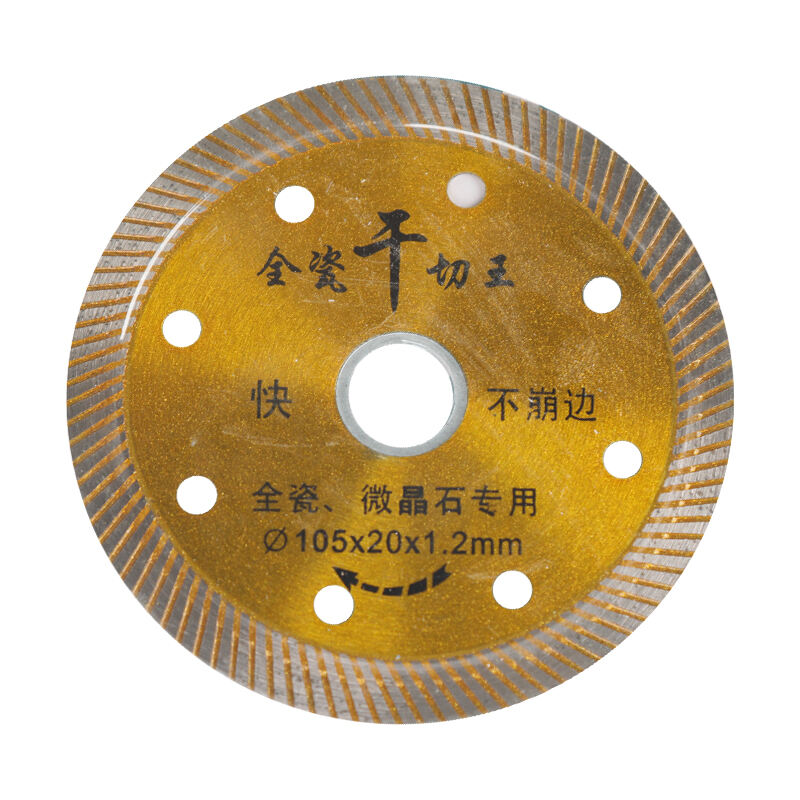

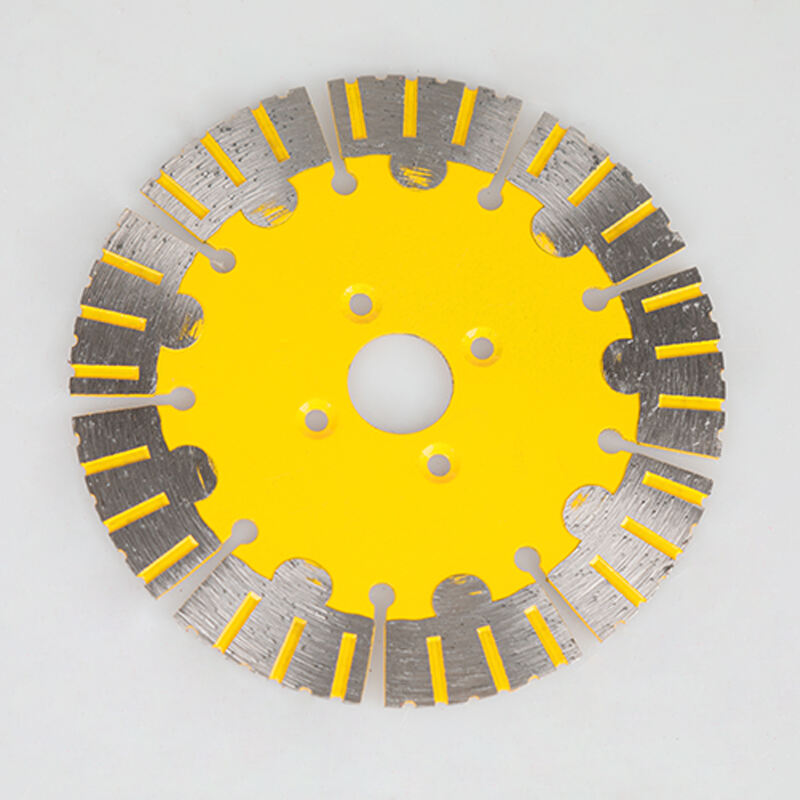

Metal Disc for Industrial Applications: Versatile and Durable Industrial Component

These discs meet the needs of different industries, from Mechanics Parts to heavy duty mining equipment. Metal discs for industrial applications is the topic of discussion. A diverse set of applications consisting of mechanical parts, wear resistant components, or bases for other processes prove their versatility and bulk making them indispensable in power generation as well manufacturing.

Get A Quote