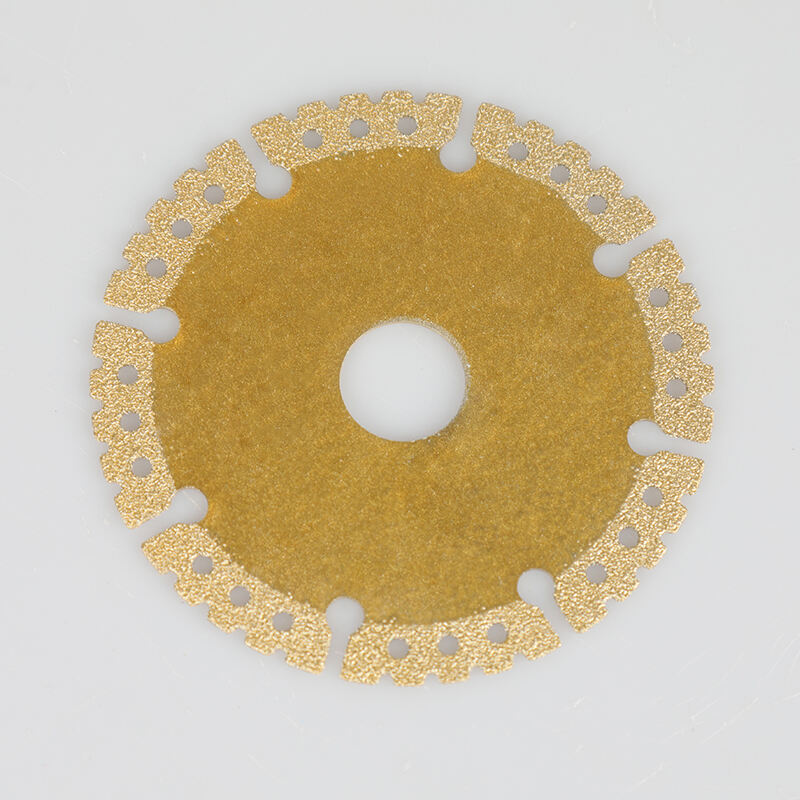

Diamond blades have to be manufactured to rigorous standards because they are meant to cut some of the diamonds hardest materials. The necessary cutting tools are formed by putting diamond grits on metal or resin bond. These blades are made from high quality tools which assist construction workers in achieving efficiency in their work, wherediamond blades are exemplary diamonds as well. For instance, blades serve for cutting concrete, asphalt and even lifted steel structures. The reputation associated with such tough blades is wide and well This can help their brand. The kind of lifting materials gripped also determines the reputation a user can gain, with blades known to make or break silence when smooth cutting ends are employed. A diamond blade grinding tool can take apart rigid components with infrequent replacements. These tools ought to be accompanied as little as possible, especially alone when not in use.