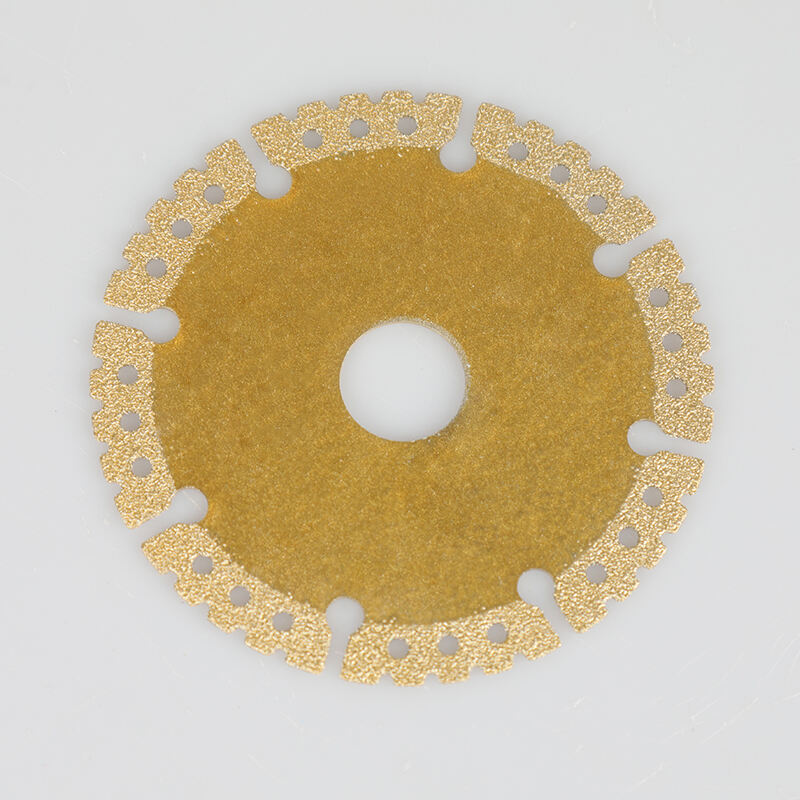

Taking advantage of diamonds' unparalleled hardness and sharpness, precision diamond cutting is classified among the most specialized operations in the industry. In the optical industry, prisms and lenses undergo diamond cutting at a micron level. For effective OD grinding, incredibly powerful diamond-tipped cutting tools are employed, while eye polishing machines meticulously engineered to inspect geometric fidelity eye optical components. With the growth of the electronics industry, face sawing of delicate electronic components such as printed circuit boards now integrate precision diamond cutting. The desired level of accuracy is achieved with advanced CNC machines operated by skilled technicians.