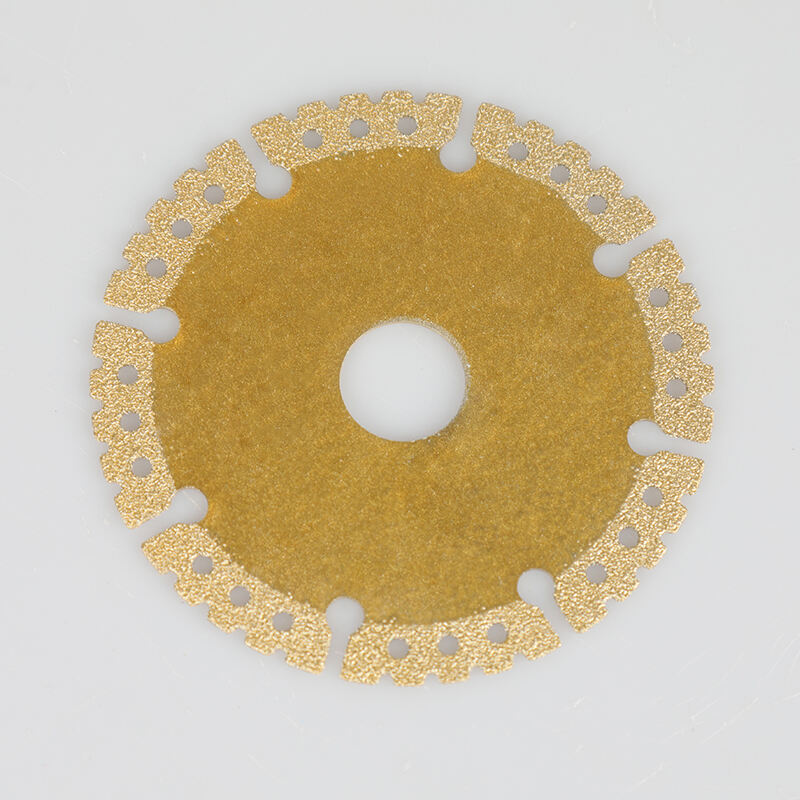

The steps executed with the utmost care while performing precise diamond cutting rest on the unparalleled hardness of the diamond that allows it to cut strong materials with speed and precision. This is done with tools such as diamond tipped saw blades and diamond impregnated grinding wheels. In the stone industry, diamonds are employed in the cutting of marble and granite along with several other hard stones. The reason why the cutting process is so efficient is due to the fact that diamonds remain sharp throughout the cutting process thereby reducing the need for frequent changes of the tools. Moreover, other modern methods of cutting such as water jet assisted diamond cutting are more efficient because they cool and clean the area around the cut while the swift removal of the materials happens.