Optimize Cutting Parameters for Maximum Diamond Cutting Disc Longevity

Matching RPM and Feed Rate to Material Hardness and Blade Specifications

Precise calibration of rotational speed and feed pressure is foundational to diamond cutting disc longevity. Exceeding manufacturer-recommended RPM ranges accelerates segment wear by up to 38%, especially when cutting dense, abrasive materials like reinforced concrete or quartzite (NIST 2023). For optimal performance:

- Maintain peripheral speeds between 500–5,000 surface feet per minute (SFPM), adjusted for material abrasiveness

- Reduce feed rates by 15–20% when transitioning from soft asphalt to hard granite

- Match blade bond hardness to substrate—softer bonds for abrasive materials (e.g., green concrete), harder bonds for dense, low-abrasion substrates (e.g., cured granite)

Reducing Vibration and Excessive Force to Prevent Segment Fracture

Lateral pressure and machine instability induce micro-fractures in diamond segments, directly compromising structural integrity and thermal resilience. Operators should:

- Use guide rails or laser alignment systems to minimize blade deflection and maintain consistent kerf geometry

- Apply steady, moderate feed pressure—avoid intermittent heavy force that spikes localized heat and stress

- Inspect equipment mounts monthly for arbor wear, flange deformation, or misalignment

Thermal stress from friction—not just ambient temperature—is the leading contributor to premature segment failure. Parameter optimization must therefore precede cooling implementation, as even ideal water flow cannot fully compensate for excessive mechanical loading.

Implement Effective Cooling Strategies to Protect Diamond Cutting Disc Integrity

How Continuous Wet Cooling Prevents Thermal Shock and Bond Degradation

Continuous wet cooling remains the most effective method for preserving diamond segment integrity during high-heat operations. When cutting abrasive materials like concrete or asphalt, interface temperatures can exceed 600°F (NIST 2023), triggering three interrelated failure mechanisms:

- Thermal shock: Rapid cooldown after overheating generates micro-cracks in the sintered metal bond

- Bond degradation: Metal matrix softening begins above 300°F, reducing diamond retention

- Graphitization: In oxygen-rich environments, diamonds begin converting to graphite above 1500°F

Sustained water flow maintains disc temperatures below 200°F—well under critical thresholds—preserving bond strength and diamond exposure. According to the Industrial Diamond Association, discs operated under optimized wet cooling last 2.8× longer than those subjected to marginal water supply.

Wet vs Dry Cutting: Real-World Lifespan Gains (Up to 3× with Proper Water Flow)

While dry cutting offers portability and convenience, lifecycle data confirms its steep trade-off in durability:

| Cutting Method | Average Lifespan | Key Failure Modes |

|---|---|---|

| Dry Cutting | 15–20 cuts | Segment fracture, bond erosion, blade warping |

| Wet Cutting (Minimal Flow) | 30–40 cuts | Partial diamond pullout, uneven wear |

| Wet Cutting (1.5 GPM Flow) | 60+ cuts | Gradual, uniform wear only |

Getting proper cooling right can extend tool life by three times or more, not just because things get a little better, but because it stops those main heat damage problems at their source. When flow rates drop below 1 gallon per minute for every inch of blade diameter, heat starts building up in dangerous ways. That's why most experts recommend aiming for between 1.5 and 2 gallons per minute to make sure everything gets properly cooled down. The nozzles should be placed no more than six inches away from where the actual cutting happens. Check that coolant actually reaches both sides of the cut area too. Localized overheating is a real problem, causing about 78 percent of early segment failures according to Machinery Journal in 2023.

Select and Install the Right Diamond Cutting Disc for Your Application

Aligning Segment Design (Concentration, Hardness, Geometry) with Target Material

Matching segment design to material characteristics isn't just important—it's absolutely essential for getting the most out of cutting tools. When aligned properly, tool life can actually increase anywhere from 40 to 60 percent. Hard materials that don't wear down much, such as granite or quartz, generally need softer bonding agents with around 20 to 30 percent diamond concentration. This setup allows the matrix to wear at a controlled rate while keeping fresh diamonds exposed during operation. On the flip side, when dealing with softer but abrasive surfaces like asphalt or newly poured concrete, tougher bonds with concentrations between 35 and 45 percent are better suited to withstand quick erosion. The geometry aspect matters too. Segmented rim designs tend to perform best when there's lots of debris flying around in masonry applications. Continuous rims give cleaner cuts without vibrations when working on delicate tiles. Turbo configurations strike a nice balance between speed and longevity for everyday jobs. Never forget to double check what the manufacturer recommends though. Using the wrong type of bond hardness can slash tool life by nearly three quarters either through glazing issues with hard bonds against abrasive materials or undercutting problems when soft bonds meet tough surfaces.

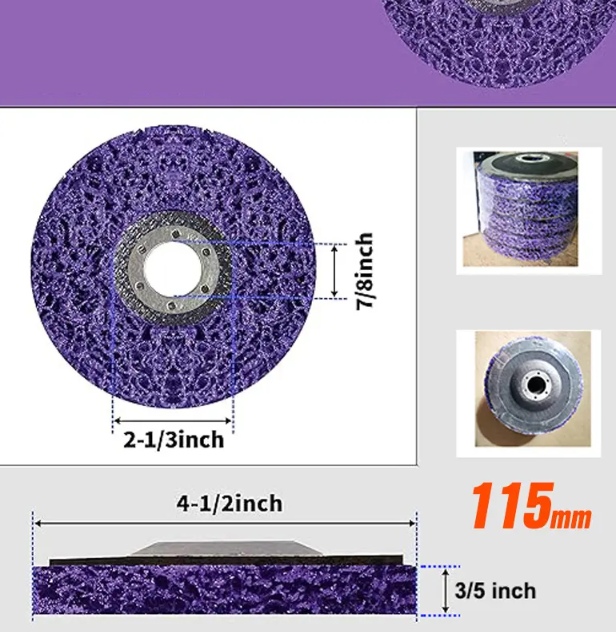

Ensuring Flange Alignment, Arbor Fit, and Mounting Stability to Avoid Runout Damage

Runout—the deviation of the disc’s rotational plane from true concentricity—is the leading mechanical cause of segment fracture and uneven wear. Prevention starts at installation:

- Clean flanges thoroughly and tighten evenly to manufacturer torque specs (typically 40–60 N·m)

- Confirm arbor fit: any play exceeding 0.1 mm introduces destabilizing vibration

- Verify parallel alignment—flanges must seat flat against the disc without gaps

- Inspect spindles for bends; even minor deformation increases wobble by 3×

- Perform a manual spin test: deviation must remain under 1 mm

Runout under 0.3 mm significantly extends disc life by preventing heat-spot formation and micro-fracture propagation. Recheck alignment after the first few cuts—initial loading often reveals subtle instability that worsens with use.