Wet and dry grinding are two essential processing methods in the industrial field, widely used in mechanical manufacturing, automotive maintenance, furniture processing, metal polishing and many other industries. The key to ensuring efficient and high quality grinding results lies in choosing the right abrasive cloth, as different abrasive cloth types have distinct performance characteristics that determine their adaptability to wet and dry grinding environments. Established in 1996, Dongtai Abrasives is a national high tech enterprise and a professional coated abrasives company integrating research and development, production, sales and services. With advanced production equipment, strict quality control and rich industry experience, we have been committed to providing high quality abrasive cloth products suitable for wet and dry grinding, meeting the diverse application needs of global customers.

Understanding Wet and Dry Grinding and Their Core Requirements

To choose the right abrasive cloth for wet and dry grinding, it is first necessary to clarify the differences between wet and dry grinding, as well as their unique requirements for abrasive cloth performance. Both wet and dry grinding play an important role in industrial processing, but their working principles and application scenarios are quite different, which directly affects the selection of abrasive cloth.

What Is Wet Grinding and Its Requirements for Abrasive Cloth

Wet grinding refers to a grinding method that adds water or special cooling liquid during the processing process. The cooling liquid can not only reduce the temperature generated by friction between the abrasive cloth and the workpiece, prevent the workpiece from being deformed by high temperature, but also wash away the grinding debris in time, avoid the abrasive cloth from being blocked, and improve the grinding precision and surface finish of the workpiece. For abrasive cloth used in wet grinding, the core requirement is water resistance. The adhesive and base material of the abrasive cloth must have good water resistance to avoid the abrasive grains falling off or the base material becoming soft and damaged after contact with water. In addition, the abrasive cloth for wet grinding also needs to have strong wear resistance and corrosion resistance to adapt to the long-term contact with cooling liquid and grinding debris.

What Is Dry Grinding and Its Requirements for Abrasive Cloth

Dry grinding is a grinding method that does not use any cooling medium, which is widely used in scenarios where cooling liquid is not suitable or convenient to use, such as outdoor processing and quick repair. The biggest challenge of dry grinding is the high temperature generated by friction, which not only tests the high temperature resistance of the workpiece, but also puts forward higher requirements on the abrasive cloth. The abrasive cloth for dry grinding must have excellent high temperature resistance, and the adhesive should not soften or decompose under high temperature conditions, so as to ensure the stability of the abrasive grains. At the same time, the abrasive cloth for dry grinding needs to have good air permeability and anti clogging performance, so that the grinding debris can be discharged in time, avoid affecting the grinding efficiency and the surface quality of the workpiece. In addition, the abrasive cloth for dry grinding also needs to have high toughness to adapt to the high-speed friction during dry grinding.

Key Characteristics of Abrasive Cloth for Wet and Dry Grinding

Whether it is used for wet grinding or dry grinding, the abrasive cloth needs to have certain core characteristics to ensure stable performance and good grinding effect. These characteristics are not only related to the quality of the abrasive cloth itself, but also directly affect the application effect of wet and dry grinding. Dongtai Abrasives has optimized the production process and material selection according to the characteristics of wet and dry grinding, making our abrasive cloth fully meet these core requirements.

Water Resistance and High Temperature Resistance

Water resistance and high temperature resistance are the two most critical characteristics of abrasive cloth for wet and dry grinding. For wet grinding, the abrasive cloth must be able to withstand long-term immersion in cooling liquid without damage; for dry grinding, it must be able to resist high temperature generated by friction. Dongtai Abrasives uses high-quality resin adhesive and waterproof base material to produce abrasive cloth, which not only has excellent water resistance, but also can maintain stable performance at high temperatures. Our abrasive cloth has passed strict high temperature and water resistance tests, and can adapt to the harsh working environment of wet and dry grinding.

Abrasion Resistance and Grain Adhesion

Abrasion resistance determines the service life of the abrasive cloth, and grain adhesion determines the stability of the grinding effect. In wet and dry grinding, the abrasive cloth is in long-term high-speed friction with the workpiece, so it must have strong wear resistance. Dongtai Abrasives selects high-quality abrasive grains, and uses advanced bonding technology to firmly bond the abrasive grains to the base material, which not only improves the wear resistance of the abrasive cloth, but also avoids the abrasive grains falling off during the grinding process, ensuring the consistency of the grinding effect. The service life of our abrasive cloth is 30% longer than that of ordinary abrasive cloth, which can effectively reduce the production cost of customers.

Flexibility and Adaptability

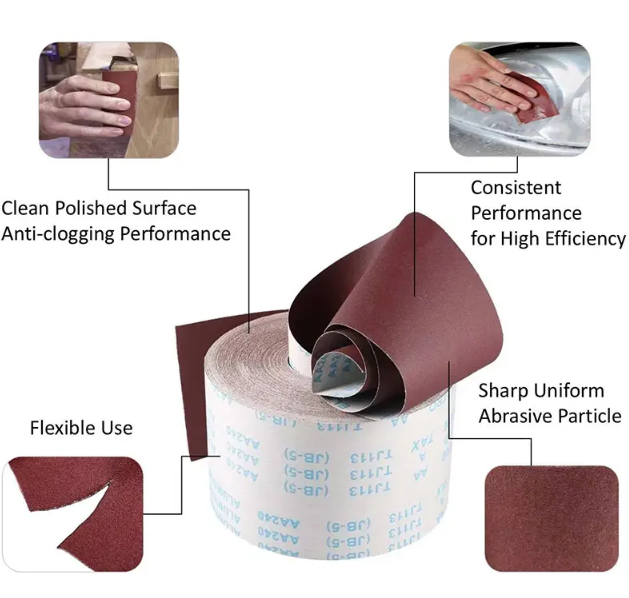

In wet and dry grinding, the workpiece shape is diverse, so the abrasive cloth needs to have good flexibility to fit the surface of the workpiece, ensuring that every part of the workpiece can be evenly ground. Dongtai Abrasives optimizes the thickness and material of the base material, making the abrasive cloth have good flexibility and ductility, which can adapt to the grinding of workpieces of different shapes and sizes. Whether it is flat grinding, curved surface grinding or edge grinding, our abrasive cloth can play an excellent role.

Which Abrasive Cloth Types Are Suitable for Wet and Dry Grinding

Not all abrasive cloth types are suitable for wet and dry grinding. According to the characteristics of wet and dry grinding and the performance of different abrasive cloth, we can screen out the most suitable abrasive cloth types. Combined with years of production and R & D experience, Dongtai Abrasives summarizes the following several abrasive cloth types suitable for wet and dry grinding, which can meet the different application needs of customers.

Resin Bonded Coated Abrasive Cloth

Resin bonded coated abrasive cloth is the most suitable type for wet and dry grinding, which is also the core product of Dongtai Abrasives. This type of abrasive cloth uses high-quality resin as the adhesive, which has excellent water resistance and high temperature resistance. It can be used for both wet grinding and dry grinding, and has stable performance in both working environments. Resin bonded coated abrasive cloth has strong wear resistance and grain adhesion, and can be used for grinding various materials, such as metal, wood, plastic and so on. Dongtai Abrasives is equipped with 37 of the most advanced automated machines in the world to produce resin bonded coated abrasive cloth, with an annual production capacity of over 11 million square meters of coated abrasives, which can meet the large demand of global customers.

Silicon Carbide Abrasive Cloth

Silicon carbide abrasive cloth is mainly suitable for wet grinding, and also can be used for light dry grinding. Silicon carbide abrasive grains have high hardness and sharp edges, which can achieve efficient grinding and fine surface finish. The silicon carbide abrasive cloth produced by Dongtai Abrasives uses high-purity silicon carbide abrasive grains and waterproof resin adhesive, which has excellent water resistance and wear resistance. It is especially suitable for wet grinding of hard materials, such as stainless steel, glass, ceramics and so on. In wet grinding, the silicon carbide abrasive cloth can effectively reduce the grinding temperature, avoid the workpiece from being burned, and improve the surface quality of the workpiece. Our silicon carbide abrasive cloth is exported to nearly 50 countries and regions, and has won wide praise from customers for its excellent performance.

Aluminum Oxide Abrasive Cloth

Aluminum oxide abrasive cloth is mainly suitable for dry grinding, and also can be used for mild wet grinding. Aluminum oxide abrasive grains have good toughness and wear resistance, and can withstand high temperature generated by dry grinding. The aluminum oxide abrasive cloth produced by Dongtai Abrasives uses high-quality aluminum oxide abrasive grains and high-temperature resistant resin adhesive, which can maintain stable performance during dry grinding. It is suitable for dry grinding of metal materials, such as carbon steel, iron, copper and so on. In mild wet grinding, the aluminum oxide abrasive cloth can also play a good role, but it is not suitable for long-term immersion in cooling liquid. Dongtai Abrasives can customize aluminum oxide abrasive cloth of different specifications according to the customer's application needs.

Application Scenarios of Abrasive Cloth in Wet and Dry Grinding

Abrasive cloth has a wide range of application scenarios in wet and dry grinding, covering many industries such as mechanical manufacturing, automotive maintenance, furniture processing, metal polishing and so on. Understanding the application scenarios of abrasive cloth in wet and dry grinding can help customers choose the most suitable abrasive cloth type, and give full play to the performance of the abrasive cloth and the effect of wet and dry grinding.

Mechanical Manufacturing Industry Application

In the mechanical manufacturing industry, wet and dry grinding are widely used in the processing of mechanical parts. The abrasive cloth is used to grind the surface of the parts, remove burrs and unevenness, and improve the precision and surface finish of the parts. For example, in the processing of gears, shafts and other parts, dry grinding is usually used to remove the burrs on the surface of the parts, and wet grinding is used to achieve fine grinding of the parts surface. Dongtai Abrasives' resin bonded coated abrasive cloth is widely used in the mechanical manufacturing industry, which can meet the high-precision grinding needs of mechanical parts, and improve the production efficiency and product quality of enterprises.

Automotive Manufacturing and Maintenance Application

In the automotive manufacturing and maintenance industry, wet and dry grinding are mainly used in the grinding of automotive body, engine parts and brake parts. For example, in the automotive body repair, wet grinding is used to grind the paint surface of the body, so as to ensure the flatness and smoothness of the paint surface; in the maintenance of engine parts, dry grinding is used to remove the carbon deposit and rust on the surface of the parts. The silicon carbide abrasive cloth and resin bonded coated abrasive cloth produced by Dongtai Abrasives are widely used in the automotive industry, which have excellent grinding effect and can adapt to the harsh working environment of automotive manufacturing and maintenance. Our products are exported to Europe, America, South Korea and other countries and regions, and are favored by many automotive manufacturers and maintenance enterprises.

Furniture and Wood Processing Application

In the furniture and wood processing industry, wet and dry grinding are used to grind the surface of wood, remove the rough surface and burrs, and improve the smoothness and beauty of the wood surface. Dry grinding is usually used for the initial grinding of wood, to remove the large burrs and unevenness on the surface; wet grinding is used for the fine grinding of wood, to make the wood surface more smooth and delicate. Dongtai Abrasives' aluminum oxide abrasive cloth and resin bonded coated abrasive cloth are suitable for wood processing. They have good flexibility and can fit the surface of wood, ensuring the grinding effect. Our abrasive cloth can be used for grinding various woods, such as solid wood, plywood, MDF and so on.

Metal Polishing Industry Application

In the metal polishing industry, wet and dry grinding are the core processes to improve the surface finish of metal products. The abrasive cloth is used to polish the surface of metal products, remove the oxide layer and scratches on the surface, and make the metal surface show a bright luster. For example, in the polishing of stainless steel products, wet grinding is used to achieve fine polishing, and dry grinding is used to remove the oxide layer on the surface. Dongtai Abrasives' silicon carbide abrasive cloth has excellent polishing effect, which can make the metal surface reach a mirror like finish. Our abrasive cloth is widely used in the metal polishing industry, and has won high praise from customers for its stable performance and good polishing effect.

Dongtai Abrasive Cloth: Your Reliable Partner for Wet and Dry Grinding

As a national high-tech enterprise and the vice president unit of the Abrasives Committee of the China National Hardware and Electrical Merchants Association, Dongtai Abrasives has been focusing on the production of coated abrasives for more than 20 years, integrating research and development, production, sales and services. We have strong production strength, professional R & D team and strict quality control system, which can provide customers with high-quality abrasive cloth products suitable for wet and dry grinding.

Our company covers an area of 60,000 square meters, with a high-quality team including six R & D personnel, over 160 production staff, 20 quality inspection personnel and 18 marketing staff. We are equipped with 37 of the most advanced automated machines in the world, two hardening furnaces and the most advanced quality inspection equipment in China that meets international standards. Every batch of abrasive cloth products must go through strict quality inspection before leaving the factory, ensuring that the product quality meets international standards. Our annual production capacity is over 84 million coated abrasive discs and 11 million square meters of coated abrasives, which can meet the large demand of global customers.

We hold the right to conduct direct import and export business, and our abrasive cloth products are currently exported to nearly 50 countries and regions, including Europe, America, South Korea, Southeast Asia, the Middle East, Central Asia, Africa and Latin America. Adhering to the concept of "Rising in the East, Benefiting the World", Dongtai Abrasives is committed to promoting the development of the global coated abrasives industry, and providing customers with high-quality, high-performance abrasive cloth products and professional services.

Conclusion

Choosing the right abrasive cloth is the key to ensuring the effect of wet and dry grinding. Resin bonded coated abrasive cloth, silicon carbide abrasive cloth and aluminum oxide abrasive cloth are the most suitable types for wet and dry grinding, each with its own characteristics and applicable scenarios. Resin bonded coated abrasive cloth is versatile and suitable for both wet and dry grinding; silicon carbide abrasive cloth is excellent in wet grinding, suitable for hard material processing; aluminum oxide abrasive cloth is outstanding in dry grinding, suitable for metal material processing.

Dongtai Abrasives, with more than 20 years of industry experience, strong production strength and professional R & D capabilities, can provide customers with high-quality abrasive cloth products suitable for wet and dry grinding, and customize targeted solutions according to different customer needs. Whether you are engaged in mechanical manufacturing, automotive maintenance, furniture processing or metal polishing, we can provide you with the most suitable abrasive cloth products and professional services. Choose Dongtai abrasive cloth, and let us work together to improve production efficiency and product quality.

Table of Contents

- Understanding Wet and Dry Grinding and Their Core Requirements

- Key Characteristics of Abrasive Cloth for Wet and Dry Grinding

- Which Abrasive Cloth Types Are Suitable for Wet and Dry Grinding

- Application Scenarios of Abrasive Cloth in Wet and Dry Grinding

- Dongtai Abrasive Cloth: Your Reliable Partner for Wet and Dry Grinding

- Conclusion