Understanding Flap Wheels and Polishing Wheels: Definitions and Core Functions

What Is a Flap Wheel? Construction, Abrasive Layers, and Industrial Purpose

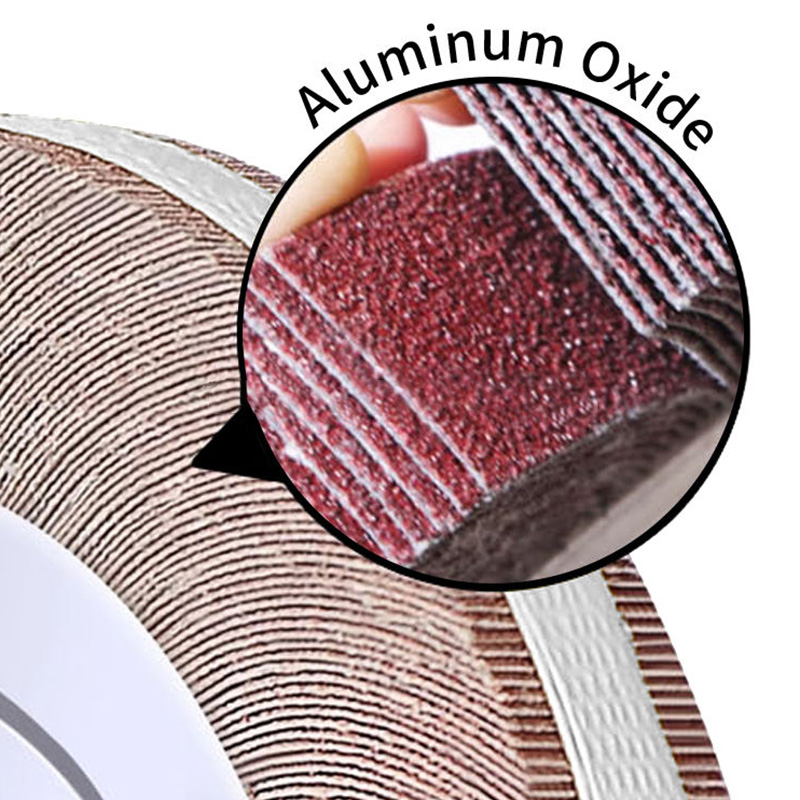

Flap wheels have those overlapping abrasive flaps usually made from either aluminum oxide or zirconia grit attached to a central hub. What makes them special is this layered construction that wears down gradually, constantly revealing new abrasive surfaces as they get used while still keeping good cutting power throughout their lifespan. Because they're so flexible, these tools can really conform to tricky shapes such as weld lines on cars or the curves of various metal components. Compared to standard grinding wheels which tend to run hot, flap wheels stay cooler during operation. That's why many technicians prefer them when working on edge blending projects, getting rid of stubborn rust spots, or getting surfaces ready for paint jobs. From fixing up damaged vehicles in body shops to cleaning castings in foundries and even polishing airplane parts, flap wheels have become indispensable across multiple industrial sectors where precision matters most.

What Is a Polishing Wheel? Materials, Design, and Role in Finishing Processes

Most polishing wheels are made from materials that can bend and flex easily, including cotton, felt, or those synthetic fabric blends we see so much these days. Many manufacturers embed them with tiny abrasive particles such as diamond dust or cerium oxide to get that extra bit of grit. The whole point is to refine surfaces down to the last scratch, creating those glossy mirror effects that make things look brand new again. Jewelers love them for finishing rings and pendants, while car detailers rely on them to restore paintwork shine without stripping away too much material. There's also something called a buffing wheel which works differently. These typically have loose fibers sticking out all over and are great for applying wax or protective coatings right onto the surface, giving items that final professional finish people really notice when they first lay eyes on something polished properly.

Key Functional Differences: Material Removal vs. Surface Refinement

- Flap Wheels: Engineered for rapid stock removal and deburring, they remove material 30–50% faster than rigid discs (2023 abrasives benchmarking).

- Polishing Wheels: Focus on surface enhancement, reducing surface roughness (Ra) from 0.8µm down to ≤0.1µm for optical-grade results.

While flap wheels excel in aggressive shaping and preparation, polishing wheels deliver high-gloss, defect-free finishes. These tools serve distinct roles and are typically combined in multi-stage finishing workflows rather than substituted for one another.

Material Composition and Structural Design: Flap Wheel vs Polishing Wheel

Flap Wheel Build: Overlapping Abrasive Flaps for Durability and Conformability

Flap wheels have several layers of abrasive material, usually made from either aluminum oxide or silicon carbide, arranged around a solid center piece. When these flaps overlap each other, they spread out the pressure when working on materials, which makes them really good at taking off material from curved or irregular shapes. There's space between each flap too, and that helps cool things down during operation while also preventing the wheel from wearing out too quickly. Some recent research in the abrasives industry suggests that because of how they're built, flap wheels tend to last about 30 percent longer than regular grinding discs when used for blending metals together.

Polishing Wheel Materials: Cloth, Fiber, and Non-Woven Fabrics for Buffing

The best polishing wheels are made from soft, porous stuff like cotton, felt, or those synthetic non woven fibers that can grab onto polishing compounds and let them out slowly over time. What makes these materials so good is how they take off barely any base metal at all while still getting rid of those tiny little scratches we can't even see with our eyes. The way these wheels are built with lots of space between the fibers actually helps them stay cool when spinning really fast, which stops things from overheating. This matters a lot when working on delicate jobs such as fixing up car paint after accidents or doing fine work on gold and silver surfaces where too much heat could ruin everything.

How Material Choice Impacts Performance and Longevity

| Factor | Flap Wheel | Polishing Wheel |

|---|---|---|

| Primary Purpose | Stock removal, edge blending | Surface refinement, gloss enhancement |

| Grit Relevance | Coarse grits (24–80) for grinding | Fine grits (180–1200) for polishing |

| Heat Management | Built through layered flap spacing | Achieved via porous fabric design |

Coarse-grit flap wheels rapidly remove material but leave visible scratches, requiring follow-up polishing. In contrast, fine-grit fiber wheels produce superior finishes but wear more quickly under heavy load. Selecting the appropriate wheel based on material hardness and task requirements ensures optimal performance and cost efficiency.

Industrial and Practical Applications of Flap Wheels in Metalworking

Surface Blending and Edge Smoothing with Flap Wheels

Flap wheels work really well when it comes to blending those welded seams and getting rid of rough edges on things like car parts, steel buildings, and all sorts of industrial machinery. What makes them stand out is how they can bend and shape around odd curves and angles, giving a smooth finish without tearing into the material. Take Europe for instance – nearly three quarters of metal workers there grab a flap wheel after welding because these tools knock off those annoying little burrs without messing with the actual measurements of what they're working on. That's pretty impressive considering how delicate some precision work needs to be.

Rust Removal, Paint Stripping, and Pre-Weld Preparation

Flap wheels do a great job at removing rust and old paint from metal surfaces, getting things ready for welding or new coatings. The way these tools work is pretty clever actually the layers gradually wear away at corrosion without taking much material off the base metal itself. That makes them really good for bringing old machines back to life or fixing up structural components that have seen better days. Hook one up to an angle grinder and watch what happens. Zirconia-alumina wheels can cover big surfaces in no time at all. Some tests show they get the job done about half as fast as hand sanding, but honestly who wants to spend hours rubbing away at stubborn rust anyway?

DIY and Workshop Uses: Flap Discs for Accessible Metal Finishing

Flap discs that are compact in size work great for all sorts of projects around the shop. Hobbyists love them for things like fixing up motorcycle exhaust systems, getting rid of rough spots on 3D printed metal pieces, or bringing old hand tools back to life. Most come in different grit levels. The 80 grit ones tend to be what people grab first when they need to blend something down, whereas moving up to 120 grit gives that nice smooth finish everyone wants. What makes these discs special is how flexible they are. This lets folks get into those tricky curved areas without going too far with the grinding. Small workshop owners really appreciate this feature because it saves both time and materials that might otherwise get wasted during mistakes.

Why Flap Wheels Excel in Aggressive Stock Removal

Flap wheels beat regular grinding wheels when it comes to taking off lots of material quickly because they keep sharpening themselves and don't build up as much heat. Take ceramic grit flap wheels for instance these things can take away about 30 percent more steel every minute compared to normal grinding discs in foundries, based on some research from the Industrial Abrasives Report released last year. What makes them work so well is how the new abrasive surfaces keep coming into play as the old ones wear down. This means workers can grind those big castings and heavy forgings for longer periods without worrying about the tool losing effectiveness halfway through the job.

Polishing Wheels in High-Gloss Finishing: Automotive, Jewelry, and Precision Work

Achieving Mirror-Like Surfaces with Polishing and Buffing Wheels

Polishing wheels create those mirror-like, shiny surfaces when they mix fine grits between 0.1 and 5 microns into flexible materials like cloth, fibers, or non-woven stuff. These wheels don't actually take away lots of material but instead work on getting rid of tiny scratches that were there after previous steps. According to research published last year about abrasive tools, around 8 out of 10 car restoration experts go for non-woven wheels because they fit nicely over curved surfaces without leaving those annoying swirl patterns behind. Most shops have switched to them since they just seem to work better in real world conditions.

Buffing vs Polishing Wheels: Understanding the Finish Outcomes

People tend to mix up polishing and buffing, but they actually do very different things. Polishing wheels have those tiny abrasive particles built right into them, which fix surface problems and get surfaces down to Ra values under 0.8 microns. Then there's buffing, where instead of abrasives, the process uses friction from stuff like rouge or wax compounds to make surfaces really smooth and water resistant. This creates that nice shiny finish while also protecting the material underneath. Take stainless steel appliances as an example. Manufacturers first polish these surfaces until they hit those strict FDA smoothness requirements, then go through another step of buffing to boost their ability to resist microbes. It's all part of making sure kitchen equipment stays clean and lasts longer.

Applications in Automotive Detailing and Jewelry Manufacturing

When it comes to car detailing, wheel polishing can really bring back that clear look to headlights after years of exposure to sunlight. Some studies from Wevolver in 2024 show this process gets rid of around 90% of the yellowish film caused by sun damage. Over in the jewelry world, craftsmen work with tiny felt wheels when they need to shine those complicated gold and platinum pieces. These little tools let them get into all the nooks and crannies without messing up the fine details. The Jewelry Manufacturing Report tells us something interesting too: nearly 8 out of 10 luxury brands rely on wheels embedded with diamonds for their platinum finishes. And guess what? They run these machines super slow, under 50 revolutions per minute, so they don't generate enough heat to warp precious metals during the polishing process.

Non-Woven and Cloth Wheels for Fine Surface Enhancement

Non woven wheels mix 3D abrasives into nylon fibers which works really well for finishing jobs on die cast metals and those tricky shapes that just won't lie flat. Then there are cloth wheels that people often pair with iron oxide compounds known as rouge. These get the job done on things like watch faces and medical tools where clear surfaces matter most. According to data from Wevolver's Surface Finish Standards, switching from standard rigid discs to these specialized wheels cuts down on having to fix mistakes by around two thirds when dealing with tough materials like titanium or carbon fiber composites. That kind of efficiency makes all the difference in production settings where time equals money.

Performance Comparison and Use Case Guidance: When to Choose Each Wheel

Cutting Efficiency and Tool Life: Flap Wheels in Heavy-Duty Tasks

Flap wheels cut through materials much faster than regular polishing wheels when working on steel surfaces according to recent studies from the abrasives industry in 2023 showing they remove around 40% more material overall. What makes these tools so effective is their special layered flap construction which keeps performing well even after about 50 straight hours of grinding thanks to how they gradually wear down instead of suddenly failing. The self sharpening nature means workers don't have to replace them as often during tough jobs like getting rid of thick rust layers, smoothing out weld seams, or forming really hard metals without worrying too much about overheating and warping the actual piece being worked on.

Finish Quality, Heat Management, and Surface Sensitivity with Polishing Wheels

The 2024 Polishing Materials Report found that polishing wheels create around 30% less heat compared to flap wheels when doing finishing work. This makes them ideal for working with thin gauge metals and those sensitive to heat. Surface roughness measurements (Ra) can get down to just 0.2 micrometers with these wheels, which is way smoother than what most people see from flap wheels that usually leave surfaces at 2 to 3 micrometers roughness. Such fine finishing matters a lot in things like car trim pieces or jewelry manufacturing, where tiny flaws can really affect how good the finished product looks and feels.

Selecting the Right Abrasive Tool Based on Project Requirements

To choose the right wheel, consider these four key factors:

- Material hardness: Use flap wheels for steel and iron; polishing wheels for softer or temperature-sensitive metals.

- Stock removal needs: Opt for flap wheels when removing ≤1mm of material.

- Surface finish specifications: Sub-micron or mirror finishes require polishing wheels.

- Tool compatibility: Always verify RPM ratings match your grinder or polisher to ensure safety and performance.

Can Flap Wheels Replace Polishing Wheels? Evaluating Compatibility and Limits

Flap wheels take care of about 85 percent of all surface prep work across most factories and workshops these days. But when it comes to getting that ultra smooth finish needed for things like lenses or high end jewelry pieces, regular flap wheels just won't cut it. According to recent findings from the Polishing Materials Report released last year, standard flap wheels actually leave behind scratches that are roughly five to seven times deeper compared to what we see with proper polishing equipment. That's why many experienced technicians stick to a two step approach. They start with flap wheels to get the basic shape right, then switch over to specialized polishing wheels for the final touches. This method gives them the best of both worlds - faster results during rough work combined with that fine detail finishing that customers really want.

Table of Contents

- Understanding Flap Wheels and Polishing Wheels: Definitions and Core Functions

- Material Composition and Structural Design: Flap Wheel vs Polishing Wheel

- Industrial and Practical Applications of Flap Wheels in Metalworking

- Polishing Wheels in High-Gloss Finishing: Automotive, Jewelry, and Precision Work

- Performance Comparison and Use Case Guidance: When to Choose Each Wheel